Loden—A fabric with history. For the babies of tomorrow

In an industry dominated by synthetic materials, we're making a statement with a fabric that has protected, warmed, and breathed for centuries: genuine loden made from 100% merino wool. As the only brand in the baby industry to use genuine loden, we not only carry responsibility but also perpetuate knowledge and craftsmanship. From the selection of the finest merino wool fibers to the finishing of the fabric, the entire manufacturing process is in the hands of our trusted suppliers. We work exclusively with partners who adhere to the highest standards, ensuring that every meter of loden meets our strict quality requirements.

What's truly good for babies—and at the same time, good for our environment? This question was the starting point for Oh!Possum—and it continues to guide us today.

Certified

We found the answer not in high-tech materials, but in a fabric that has protected, warmed, and breathed for centuries: genuine, fulled loden made from 100% Merino wool. Hardly found in the baby industry, yet perfect for little ones: temperature-regulating, water-repellent, robust, and soft. For our products, we use only mulesing-free wool, tested according to OEKO-TEX Standard 100 and refined in genuine artisanal tradition – for a high-quality, durable, and responsibly crafted companion for life with children and beyond.

From Fiber to Fabric

How is Loden made

Its secret lies in a complex manufacturing process that combines traditional craftsmanship with modern technology:

Step No. 1

dyeing

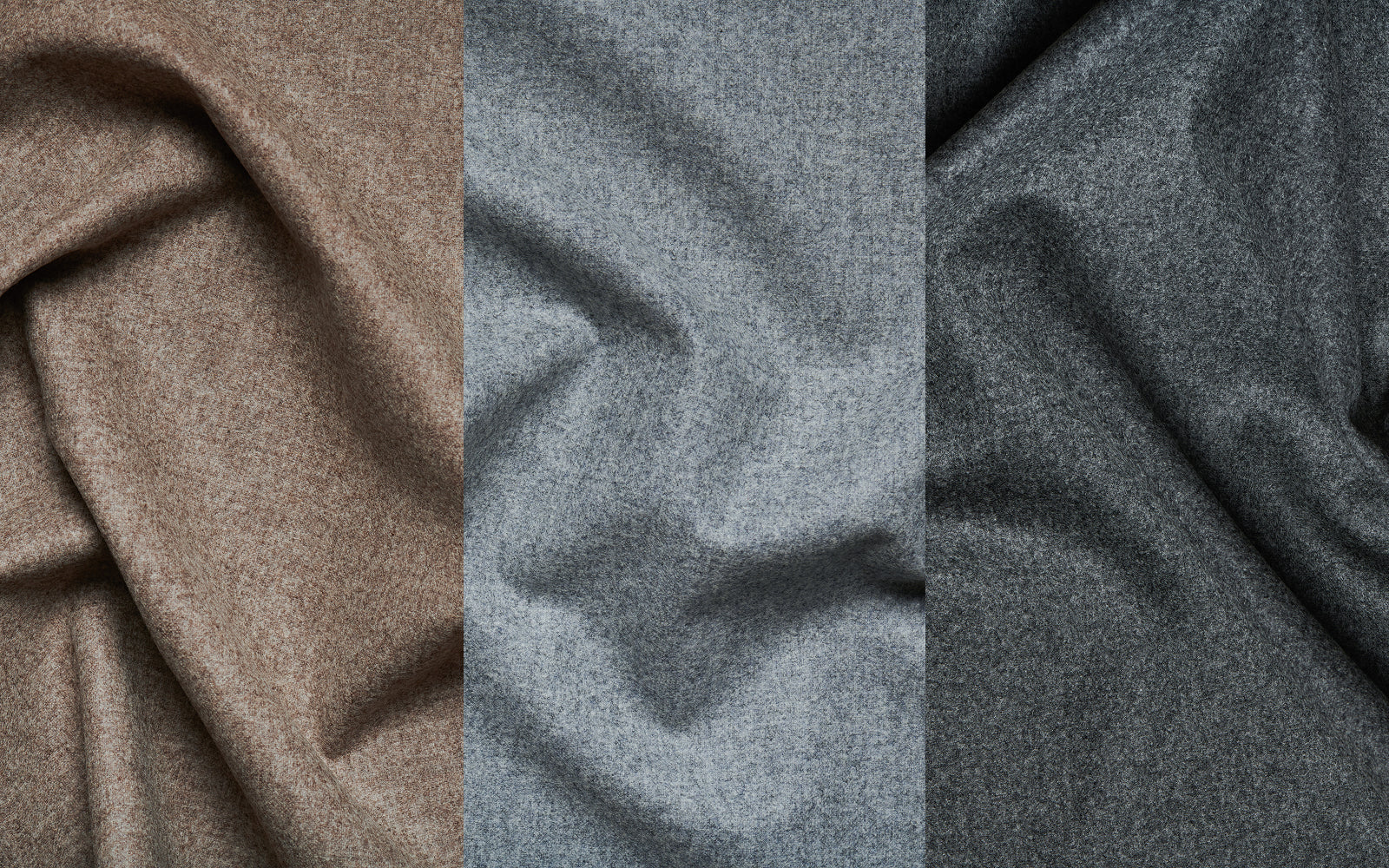

The selection of the finest wool fibers and precise dyeing according to a secret recipe ensure the characteristic color variety of our loden, preserved and archived across generations.

Step No. 2

Spiders

The dyed fibers are spun into a fine, voluminous carded yarn—ideal for fulled wool fabrics such as loden. The yarn is then inspected and cleaned to ensure consistent weaving.

Step No. 3

archipelago

During warping, up to 4,500 wool threads are wound onto a drum and bundled together to form the warp. This warp is transferred to the warp beam and further processed in the weaving mill.

Step No. 4

Weave

Warp and weft threads are woven into a fine merino fabric—up to 230 cm wide, as the fabric shrinks during fulling. Every meter is carefully inspected before finishing to guarantee the highest quality.

Step No. 5

Walking

During the fulling process, the loden shrinks by up to 30%, giving it its dense, soft texture. The original weave becomes virtually invisible—a hallmark of genuine worsted quality with an unmistakably luxurious feel.

Step No. 6

Refining

Several finishing steps give the loden its unique shine and feel. Crystal-clear Alpine water ensures exceptional softness. Some fabrics are still gently brushed with natural thistles – a process virtually unmatched in the textile industry.